As Head of Business Development & Channel at all4cloud Group, Detlef Aden is responsible for our SAP Business ByDesign AddOns and Apps. He is supported by his colleagues as well as partners around the world to get even more out of SAP Business ByDesign and provide real added value for our customers.

As a certified SAP Gold Partner and Cloud ERP expert, we develop our own solutions for SAP Business ByDesign to extend the existing functionalities. We currently support around 11,000 users around the world and have successfully deployed around 20 of our own apps.

In this article, we would like to show you the advantages and possibilities of our eam4cloud app, how transparent and uncomplicated you can organize the cooperation with external service providers regarding upcoming service orders.

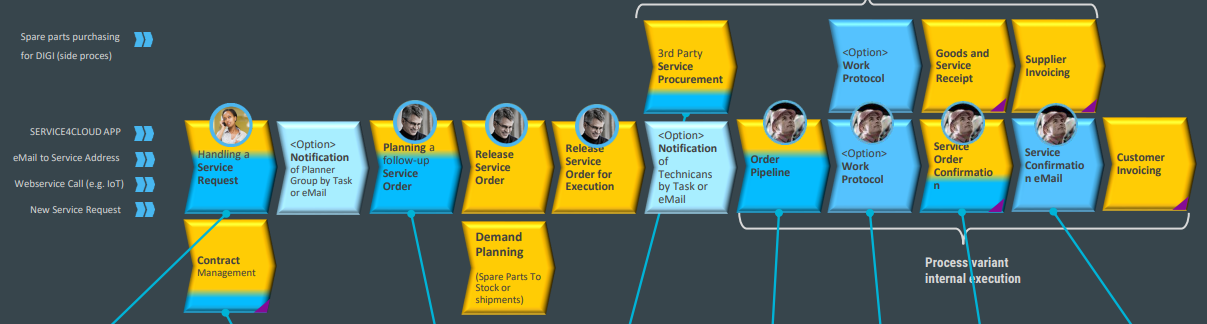

Process of work orders

Sending maintenance and repair orders to the responsible service provider in a fully automated manner and tracking the work performed conveniently in SAP Business ByDesign – that’s a big goal!

Automatically inform your employees and service providers about upcoming maintenance and service orders via email – fully integrated and directly from your ERP system with eam4cloud.

Maintenance and service orders – in the future directly from your SAP Business ByDesign.

Planned or unplanned: Maintenance of one of your machines or plants is pending or a maintenance measure is urgently required. You are now faced with the challenge of telling your employees or service providers exactly what needs to be done. In this way, you want to ensure that the work is carried out quickly and that the risk of a shutdown due to a defect is minimized or that an existing defect can be quickly repaired.

Informing the employees or service providers about the situation and their work order quickly and without wasting much time is sometimes more time-consuming than the measure itself.

Maintenance and service work that has already been carried out is often still recorded on paper. If you now want to reconstruct the history (life file) of a machine or system, you are often faced with mountains of paper – without structure, and moreover usually in the own handwriting of the responsible technician / service provider.

In addition, there is the audit-proof tracking of the work performed – information on whether the machine’s limit values are still within the normal range or whether parts need to be replaced is very valuable information. In the future, it will be possible to draw conclusions about the maintenance history, replaced parts and which technician carried out the respective measure.

Wouldn’t it be nice if all this information was available to you digitally and centrally?

Every company should use them:

Service protocols

Explore the world of digital service protocols and find out how they can add invaluable value not only to your customer contact, but also to the efficiency and transparency within your company.

Our free brochure gives you an insight into the service protocols and shows how digital service logs not only record service orders, but also create clear added value.

In the free brochure you will learn …

👉 what advantages digital service protocols offer your technicians

👉 what data should be recorded in service protocols

👉 what a practical example of digital service protocols looks like

For companies for whom operational reliability and efficiency are top priorities, there is the option of adding the necessary functions to their SAP Business ByDesign.

Integration of work orders in SAP Business ByDesign

With eam4cloud for SAP Business ByDesign, you can automatically inform employees and service providers about upcoming maintenance and repair orders directly from your ERP system. The technician / service provider receives all relevant data for the measure in question by e-mail. This includes information on the machine or system in question and the tasks that you have previously defined and that need to be completed. If defects are detected or measured values are exceeded, e.g. if the oil temperature is higher than normal, a message can be generated automatically that appears immediately (in real time) in your ERP system.

After the employee or service provider has completed his or her work order, an unchangeable, audit-proof and structured work log (PDF) is created and linked to the work order. Digital and paperless. Health and safety officers will be pleased.

Were we able to arouse your interest in eam4cloud or have you yourself identified a direct application example in your company to get started with eam4cloud? Please feel free to contact us.